|

|

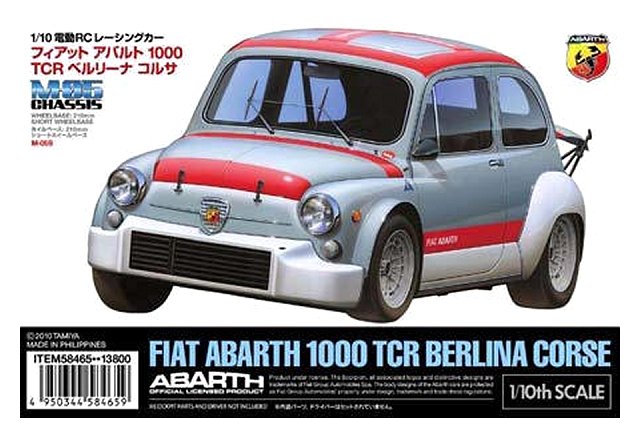

Tamiya Fiat Abarth 1000 TCR Berlina Corse - 58465

|

Released by Tamiya on June 16, 2010, this Radio Controlled self assembly model, based on the short wheelbase M-05 Chassis, is of the Fiat Abarth 1000 TCR Berlina Corse that was previously released on the M-02 Chassis (#58158).

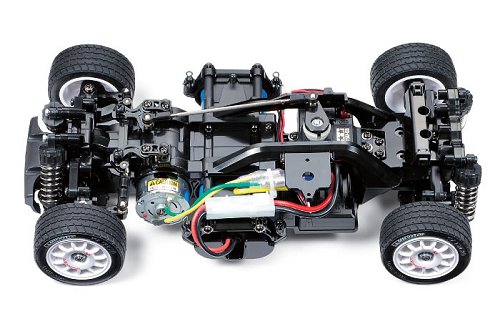

The 2WD, FWD (front wheel drive) M05 Chassis has a lower centre of gravity than previous versions and good weight distribution which coupled with four wheel independent double wishbone suspension with coil spring over friction shock absorbers, orbital bevel gear differential and a three piece steering linkage gives excellent stability and handling on high speed corners.

The M05 Chassis has three possible wheelbase options: The basic 210mm, M05M 225mm and M05L 239mm, that are set by changing the position of the rear suspension parts.

Like the majority of the Tamiya budget priced Radio Controlled models, the standard kit comes with plastic and sintered brass bush type bearings, that after a short while, when dust and grit get into them, actually wear into the metal drive shafts that spin in them. If you are building this kit to race seriously these should be replaced by steel shielded ball bearings.

To drive, the M05 Chassis has much improved balance and the low centre of gravity provides excellent stability in comparison to the first FWD short wheelbase Tamiya models, the M01 and M03. However, it still needs some skill to keep it on its wheels and just like its predecessors, provides lots of fun.

|

|

|

|

|

Tamiya Fiat Abarth 1000 TCR Berlina Corse #58465 M-05 - Chassis

|

|

Tamiya Fiat Abarth 1000 TCR Berlina Corse #58465 M-05

|

Buying a Used Tamiya Fiat Abarth 1000

|

|

|

|

|

|

Hints, Tips and Information

Rubber Tires for RC Models

Rubber Tires ALWAYS should have either soft sponge or rubber inserts. They will not function as they should without them. And if you are totally serious about your racing they should be glued to the rims. How to Mount Rubber Tires onto Wheels/Rims.

Before mounting your Tires, I would recommend talking to the more experienced racers at your local club, concerning what inserts they use. Even the top level racers rely on a bit of local knowledge on tracks they have never raced before. |

|

Hints, Tips and Information

Emergency Plastic Part Repairs

It always happens when you least expect it. You are racing hard; and suddenly some idiot decides to side swipe you' and break your front wishbone. Even though you may carry spare parts for just about everything on your car, it always seems to be the same part that breaks, and although you made a mental note the last time it happened to get a replacement you soon realise those mental notes were not worth the paper they are written on.

|

|

RC Models:

|

Radio & Motors: |

Other

Accessories: |