|

|

|

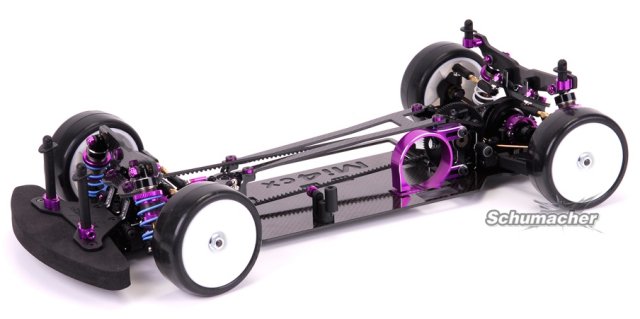

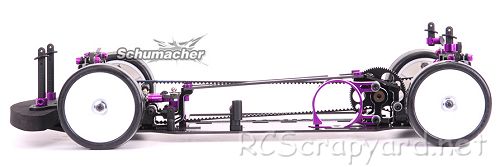

1/10 Scale Electric Rally/Touring Car:

Schumacher Mi4CX - K117 / K118

|

After winning the British championship with the Mi4LP in 2010, Chris Granger helped develop the Mi4CX, based on his winning car.

Because of the increased torque requirements of the modern RC model touring car, for the Mi4CX, Schumacher replaced the old blade drive shafts, that were prone to high wear, with brand new CVD (Constant Velocity Drive) high tensile steel drive shafts, with larger, harder wearing, pins and joints.

To race the Schumacher Mi4CX, it must be fine tuned to improve handling, provide responsive steering and give you the grip to cruise around corners at high speed, without slipping off the track. Small adjustments can make a Big difference and our step by step procedure, will guide you to the best Set-up for your individual driving style.

|

|

|

|

|

★ Schumacher Mi4CX ★

★ Schumacher Mi4CX ★

★ Schumacher Mi4CX ★

★ Schumacher Mi4CX ★

|

Buying a Used Schumacher Mi4CX

|

|

Manufacturers and Brands Catalogued, Listed and Reviewed by RC-Scrapyard.

At present, the RC Model Manufacturers, Brands and Distributors covered by us are: ABC Hobby, Academy, Acme Racing, Agama Racing, Amewi, Ansmann Racing, ARRMA, Team Associated, Atomic RC, Axial, AYK, Bolink, BSD Racing, Capricorn, Carisma, Carson, Caster Racing, Cen, Corally, Custom Works, Durango, Duratrax, ECX - Electrix, Exceed RC, FG Modellsport, FS-Racing, FTX, Fujimi, Gmade, GS-Racing, Harm, HBX, Helion, Heng Long, Himoto Racing, Hirobo, Hitari, Hobao, Hong-Nor, Hot Bodies, HPI, HSP, Intech, Integy, Jamara, JQ Products, Kawada, Kyosho, Losi, LRP, Maisto, Mardave, Marui, Maverick, MCD Racing, Megatech, Mugen, New Bright, Nichimo, Nikko, Nkok, Ofna, Pro-Pulse, Protech, PTI, RC4WD, Redcat Racing, RJ-Speed, Robitronic, Schumacher, Seben, Serpent, Smartech, Sportwerks, Step-Up, Tamiya, Team-C Racing, Team Magic, Thunder Tiger, Tomy, Top Racing, Traxxas, Trinity, Tyco, Vaterra RC, Venom, VRX Racing, WLToys, X-Factory, Xmods, Xpress, Xray, XTM, Yankee RC, Yokomo, ZD Racing and Zipzaps. |

|

Hints, Tips and Information Make your RC Model Ball Bearings Work for You

If you are serious about your racing, looking after your bearings is essential if you are to remain competitive. |

|

Hints, Tips and Information Electric Motors for RC ModelsWinds and Turns

Q/ What does 15x2 or 17x3 mean? |

|

RC Models:

|

Radio & Motors: |

Other

Accessories: |