|

|

|

1/12 Scale Electric Pan Car:

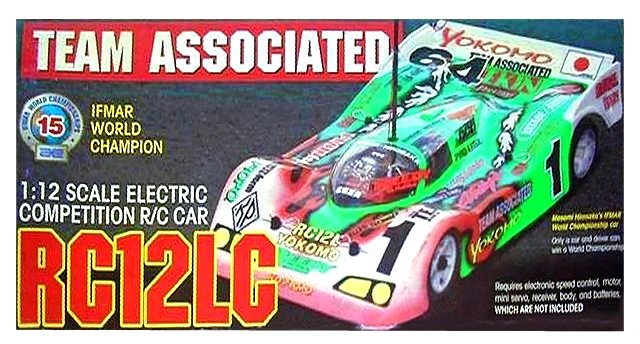

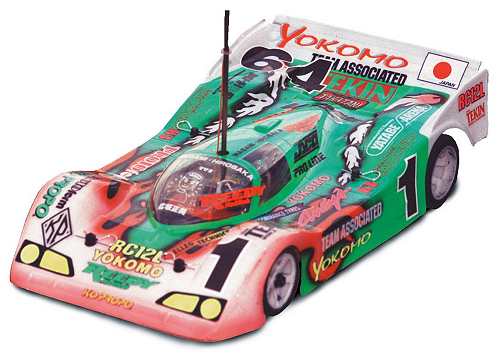

Team Associated RC12LC - 4014

|

Introduced by Team Associated in 1996, the RC12LC Graphite kit - # 4014 - was designed by Cliff Lett and won the IMFAR World Championships driven by Masami Hirosaka in the same year.

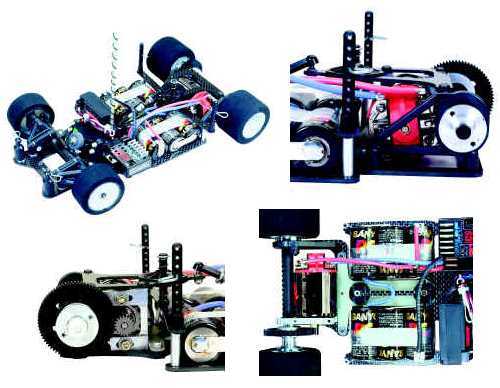

Based on the successful RC12LS, with dynamic strut front suspension, the pan chassis, came with a ball differential, coil spring over oil filled damper, adjustable friction plate, with new symmetrical T-bar and braces.

To race the Team Associated RC12LC, it must be fine tuned to improve handling, provide responsive steering and give you the grip to cruise around corners at high speed, without slipping off the track. Small adjustments can make a Big difference and our step by step procedure, will guide you to the best Set-up for your individual driving style.

|

|

|

★ Team Associated RC12LC ★

★ Team Associated RC12LC Chassis ★

|

Buying a Used Radio Controlled Model

|

|

Manufacturers and Brands Catalogued, Listed and Reviewed by RC-Scrapyard.

At present, the RC Model Manufacturers, Brands and Distributors covered by us are: ABC Hobby, Academy, Acme Racing, Agama Racing, Amewi, Ansmann Racing, ARRMA, Team Associated, Atomic RC, Axial, AYK, Bolink, BSD Racing, Capricorn, Carisma, Carson, Caster Racing, Cen, Corally, Custom Works, Durango, Duratrax, ECX - Electrix, Exceed RC, FG Modellsport, FS-Racing, FTX, Fujimi, Gmade, GS-Racing, Harm, HBX, Helion, Heng Long, Himoto Racing, Hirobo, Hitari, Hobao, Hong-Nor, Hot Bodies, HPI, HSP, Intech, Integy, Jamara, JQ Products, Kawada, Kyosho, Losi, LRP, Maisto, Mardave, Marui, Maverick, MCD Racing, Megatech, Mugen, New Bright, Nichimo, Nikko, Nkok, Ofna, Pro-Pulse, Protech, PTI, RC4WD, Redcat Racing, RJ-Speed, Robitronic, Schumacher, Seben, Serpent, Smartech, Sportwerks, Step-Up, Tamiya, Team-C Racing, Team Magic, Thunder Tiger, Tomy, Top Racing, Traxxas, Trinity, Tyco, Vaterra RC, Venom, VRX Racing, WLToys, X-Factory, Xmods, Xpress, Xray, XTM, Yankee RC, Yokomo, ZD Racing and Zipzaps. |

|

Hints, Tips and Information

Tires for RC ModelsSponge (Foam) Tires

Sponge Tires can be purchased either pre mounted, glued and trued on the rims, or separately. Fitting the Tires onto the rims can be messy, so here are a few tips to make it a bit easier.

|

|

Hints, Tips and Information

Look after your Gears

In RC there are a number of different gear teeth sizes we tend to use, based on two systems. Imperial and metric. |

|

RC Models:

|

Radio & Motors: |

Other

Accessories: |