|

|

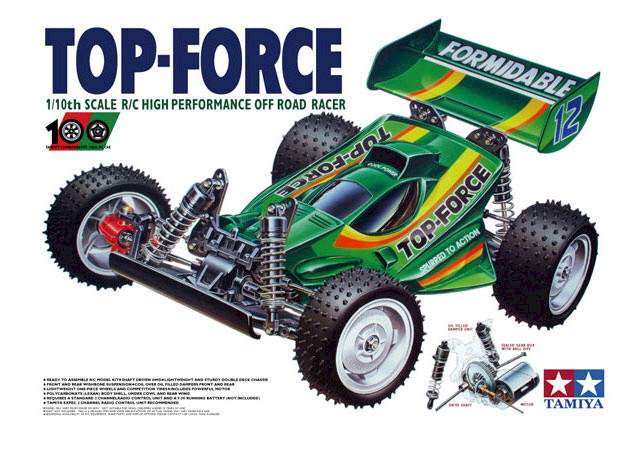

Tamiya Top Force - 58100

|

Released by Tamiya on November 26, 1991, the Top Force was basically a lightweight double deck, Fibreglass Reinforced Plate (FRP) version of the highly successful Manta Ray DF-01 chassis. The Top Force was re-released in 2005 (#58362).

Many considered the Top Force to be a vast improvement of the DF-01 chassis and on flat, less bumpy tracks, it was. But because of the lightweight construction and the double decks tendency to flex, it was not as fast "out of the box" on rugged, bumpy tracks. Less viscous damper oil and softer springs did improve the cars handling but for me it never performed to its potential.

One problem with the DF-01 chassis and its family was that if the motor mount was allowed to work loose, the pinion gear would chew up the spur gear in seconds, so you soon learned to check it after every race. Or, if you could afford it, replace it with an alloy motor mount that a local model maker made for us - that guy was brilliant.

On the positive side, front universal drive shafts and a full set of shielded ball bearings were included in the kit.

Because of the many incarnations of the DF-01, TA-01 and TA-02 chassis for many models, parts and spares for the Top Force are relatively easy to find.

|

|

|

|

|

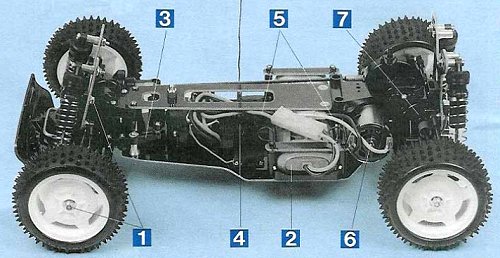

Tamiya Top Force #58100 - Chassis

|

|

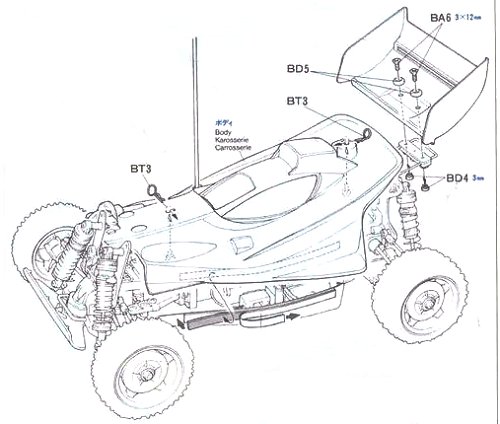

Tamiya Top Force #58100

|

Buying a Used Tamiya Top Force

|

|

|

|

|

|

Hints, Tips and Information Electric Motors for RC ModelsBrushless Motor Basics

Choosing the right Brushless motor for your needs can be a daunting task for those new to Radio Controlled Models. If you have a local club perhaps you could ask some of the more experienced members for their advice, but a little basic knowledge about the subject, so you know what questions to ask is always useful. |

Information and AdviceElectronic Speed ControllersHistory

ESC were originally developed to be used in conjunction with brushed 27T stock and modified motors in the late 1970s, early 1980s. Compared to modern day Controllers, they were Bulky and heavy, constructed using basic resistors, rheostats, capacitors and transistors, crammed together on a simple circuit board, to provide stepped but smooth acceleration when compared to the old mechanical, servo operated sweeper Speed Controllers. An Electronic Switch to change the direction of current flow was used on some of these early ESC to give reverse operation. Although they were a vast improvement on the old mechanical speedos of the time, they were expensive, jerky to control, and prone to burn out if not carefully looked after. |

|

RC Models:

|

Radio & Motors: |

Other

Accessories: |