|

|

|

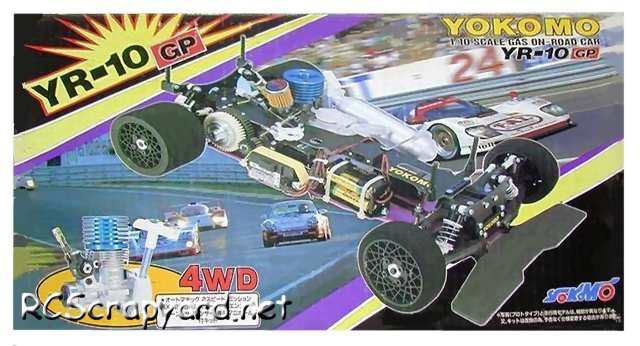

1/10 Scale Nitro Rally/Touring Car:

Yokomo YR-10 GP

|

Introduced by Team Yokomo circa 1994, the 4WD YR10 GP Touring Car, is belt driven, on an anodised alloy plate chassis, with coil spring over oil filled dampers, universal-joint drive-shafts, 2-speed transmission and a full set of ball bearings.

To race the Yokomo YR-10 GP, it must be fine tuned to improve handling, provide responsive steering and give you the grip to cruise around corners at high speed, without slipping off the track. Small adjustments can make a Big difference and our step by step procedure, will guide you to the best Set-up for your individual driving style.

|

|

|

★ Yokomo YR10-GP ★

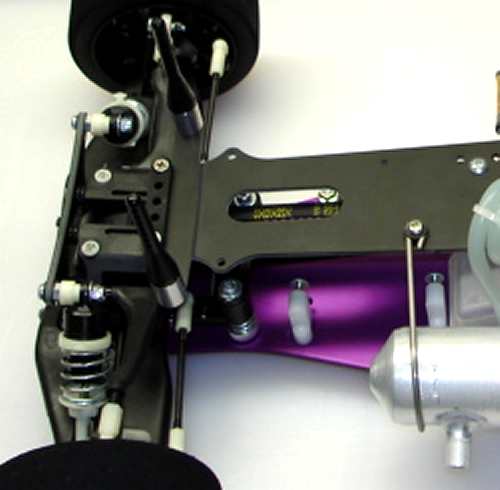

★ Yokomo YR10-GP Chassis ★

★ Yokomo YR10-GP Chassis ★

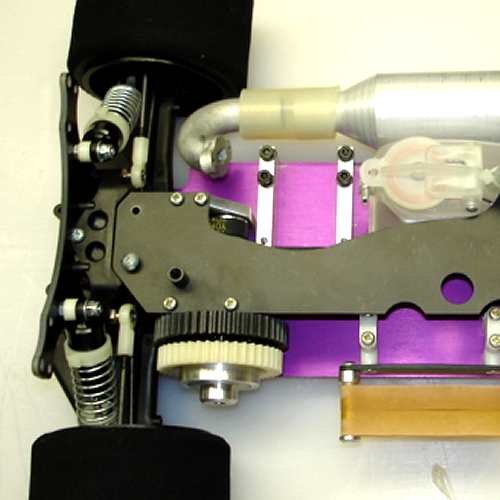

★ Yokomo YR10-GP Chassis ★

★ Yokomo YR10-GP Chassis ★

★ Yokomo YR10-GP Chassis ★

|

Buying a Used Yokomo YR-10 GP

|

|

Manufacturers and Brands Catalogued, Listed and Reviewed by RC-Scrapyard.

At present, the RC Model Manufacturers, Brands and Distributors covered by us are: ABC Hobby, Academy, Acme Racing, Agama Racing, Amewi, Ansmann Racing, ARRMA, Team Associated, Atomic RC, Axial, AYK, Bolink, BSD Racing, Capricorn, Carisma, Carson, Caster Racing, Cen, Corally, Custom Works, Durango, Duratrax, ECX - Electrix, Exceed RC, FG Modellsport, FS-Racing, FTX, Fujimi, Gmade, GS-Racing, Harm, HBX, Helion, Heng Long, Himoto Racing, Hirobo, Hitari, Hobao, Hong-Nor, Hot Bodies, HPI, HSP, Intech, Integy, Jamara, JQ Products, Kawada, Kyosho, Losi, LRP, Maisto, Mardave, Marui, Maverick, MCD Racing, Megatech, Mugen, New Bright, Nichimo, Nikko, Nkok, Ofna, Pro-Pulse, Protech, PTI, RC4WD, Redcat Racing, RJ-Speed, Robitronic, Schumacher, Seben, Serpent, Smartech, Sportwerks, Step-Up, Tamiya, Team-C Racing, Team Magic, Thunder Tiger, Tomy, Top Racing, Traxxas, Trinity, Tyco, Vaterra RC, Venom, VRX Racing, WLToys, X-Factory, Xmods, Xpress, Xray, XTM, Yankee RC, Yokomo, ZD Racing and Zipzaps. |

|

Hints, Tips and Information

Painting a Lexan Body Shell.

Most RC Model kits come with an unpainted, clear Lexan plastic Body Shell you yourself must prepare and paint. This type of Body Shell is painted on the inside, and special spray or brush on Polycarbonate Paints MUST be used.

|

|

Hints, Tips and Information

Choosing the right Tire Inserts

Once upon a time, all RC model tires were equal - they were all trash. None of the old tires had any kind of internal support, because the hard compound they were made of didn't need it. But that was before the newer soft compounds were developed. These new tires were so soft that if some kind of insert was not used they would just lay flat under the weight of the car. Thus, the new science of tire inserts was born. Inserts for Off-Road Tires

The basic soft foam inserts that come with many off-road rubber tires can be in one of two types. They can be basic rings of sponge, or the cheap and nasty strips of sponge. Many of the latest foam inserts now come pre-shaped, but more than often, they will need some work done to them before they are inserted into the tires. |

|

RC Models:

|

Radio & Motors: |

Other

Accessories: |