|

|

|

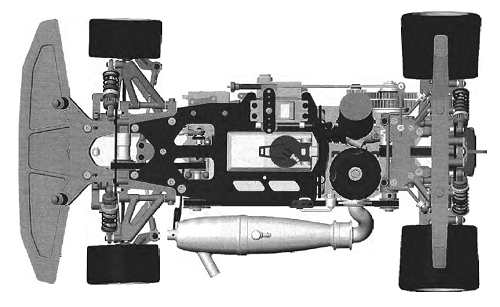

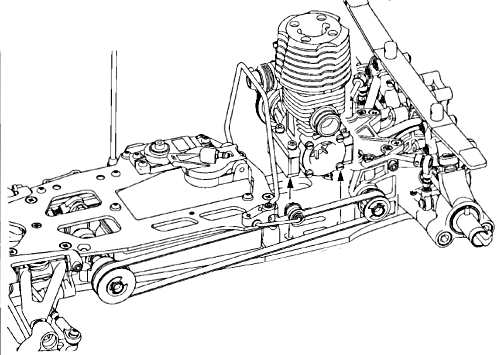

1/8 Scale Nitro Rally/Touring Car:

Mugen MRX-3 - H0060

|

Introduced by Mugen Seiki circa 2001, the 4WD MRX-3 Racing Car - H0060 - was designed by team driver Koji Sanada.

The model is belt driven, on an alloy plate chassis, coil spring over oil filled dampers, dogbone drive-shafts, 2-speed transmission and a full set of ball bearings.

To race the Mugen MRX-3, it requires time and patience, to tune and adjust for improvements in handling and steering ability and to get the grip you need to stay on course when manoeuvring around tight, slippery corners. A little can be a lot when it comes to changing your cars settings and our easy methodical directions will guide you to the best Set-up to help you win and keep you winning.

|

|

|

★ Mugen MRX3 Chassis ★

★ Mugen MRX3 Chassis ★

|

Buying a Used Mugen MRX-3

|

|

Manufacturers and Brands Catalogued, Listed and Reviewed by RC-Scrapyard.

At present, the RC Model Manufacturers, Brands and Distributors covered by us are: ABC Hobby, Academy, Acme Racing, Agama Racing, Amewi, Ansmann Racing, ARRMA, Team Associated, Atomic RC, Axial, AYK, Bolink, BSD Racing, Capricorn, Carisma, Carson, Caster Racing, Cen, Corally, Custom Works, Durango, Duratrax, ECX - Electrix, Exceed RC, FG Modellsport, FS-Racing, FTX, Fujimi, Gmade, GS-Racing, Harm, HBX, Helion, Heng Long, Himoto Racing, Hirobo, Hitari, Hobao, Hong-Nor, Hot Bodies, HPI, HSP, Intech, Integy, Jamara, JQ Products, Kawada, Kyosho, Losi, LRP, Maisto, Mardave, Marui, Maverick, MCD Racing, Megatech, Mugen, New Bright, Nichimo, Nikko, Nkok, Ofna, Pro-Pulse, Protech, PTI, RC4WD, Redcat Racing, RJ-Speed, Robitronic, Schumacher, Seben, Serpent, Smartech, Sportwerks, Step-Up, Tamiya, Team-C Racing, Team Magic, Thunder Tiger, Tomy, Top Racing, Traxxas, Trinity, Tyco, Vaterra RC, Venom, VRX Racing, WLToys, X-Factory, Xmods, Xpress, Xray, XTM, Yankee RC, Yokomo, ZD Racing and Zipzaps. |

|

Hints, Tips and Information

Glow Plugs for Nitro Engines

Nitro Engines for RC Models use a system to ignite the fuel mixture that simply employs a wire coil in a small housing called a Glow Plug. To start the engine, a battery powered Starter, or Glow Igniter, is connected to the Glow Plug and electric current heats the coil to white hot, so that when you pull start your engine, the air - fuel mixture in the cylinder is ignited. With the engine now running, the starter is no longer required. Heat generated under compression is enough to keep the coil element hot enough to keep the engine running.

|

|

Hints, Tips and Information

How to Reduce the Weight of your RC Model Car

If you ever step up and enter a regional, national or international event in RC, you will find one specific rule concerning the weight of your car.

|

|

RC Models:

|

Radio & Motors: |

Other

Accessories: |