|

|

|

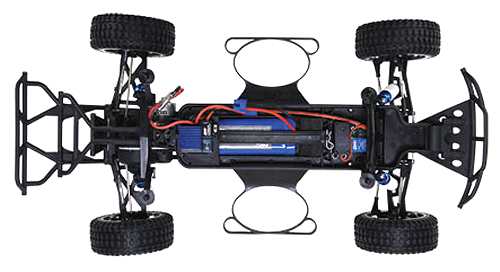

1/10 Scale Electric Truck:

Team Losi Strike - LOSB0105 - Radio Controlled TruckHistory and Info for the Losi Strike:

Released by Losi in 2009, the 2WD Strike SCT Short Course Truck - LOSB0105 - came factory assembled RTR, with a pre-painted Red or Blue lexan polycarbonate Bodyshell, Losi LM-32K 12T 550 Performance Motor, ESC, Spektrum 2.4GHz DSM Receiver and DSM Transmitter.

▼ Scroll Down for More Images ▼

|

|

|

|

★ Losi Strike ★

★ Losi Strike Chassis ★

★ Losi Strike Chassis ★

★ Losi Strike Chassis ★

★ Losi Strike Chassis ★

★ Losi Strike Chassis ★

★ Losi Strike Chassis ★

★ Losi Strike Chassis ★

★ Losi Strike Chassis ★

★ Losi Strike Chassis ★

★ Losi Strike Chassis ★

★ Losi Strike Chassis ★

★ Losi Strike Chassis ★

★ Losi Strike Chassis ★

★ Losi Strike Chassis ★

|

Buying a Used Losi Strike Truck (and What to look for)

Make a General Visual Inspection

Check the Body-Shell

If the body shell of your Losi Strike is broken, ripped or damaged in any way, this can be easily repaired with rubber solution glue. Also, for added protection and if available for your Strike model, fit an under guard to stop dirt and gravel entering the chassis. Drive Shafts and Turnbuckles

Examine the Drive System

The gearbox of your used Truck should be opened up to check for gear wear and lubrication. A thin coat of grease is often used on internal gears and although this is fine for basic running around on the back yard, if you intend to race your Truck at a higher level, this should be removed and replaced with racing oil (ZX1 or Teflon Oil). Of course, this should be reapplied after each race meeting. Pinions and Spur Gears

Don't Neglect the Ball-Joints

Ball joints always cause problems. For top level Electric Truck racing, the plastic ball connectors should be checked and if deemed necessary changed after every meeting. A simple thing like a loose fitting connector popping off could easily end your race, so better safe than sorry. Steering Servo and Servo-Saver

Stabilizers

If body roll on your Losi Strike is a problem, handling can be improved with the use of stabilizers, anti roll or sway bars, stiffer tuning springs and, or, thicker silicone oil in the dampers. Don't Forget those Bearings

▼ Scroll Down for More Articles and Advice ▼

Or, check out our RC Model Car Setup Guide

|

|

Manufacturers and Brands Catalogued, Listed and Reviewed by RC-Scrapyard.

At present, the RC Model Manufacturers, Brands and Distributors covered by us are: ABC Hobby, Academy, Acme Racing, Agama Racing, Amewi, Ansmann Racing, ARRMA, Team Associated, Atomic RC, Axial, AYK, Bolink, BSD Racing, Capricorn, Carisma, Carson, Caster Racing, Cen, Corally, Custom Works, Durango, Duratrax, ECX - Electrix, Exceed RC, FG Modellsport, FS-Racing, FTX, Fujimi, Gmade, GS-Racing, Harm, HBX, Helion, Heng Long, Himoto Racing, Hirobo, Hitari, Hobao, Hong-Nor, Hot Bodies, HPI, HSP, Intech, Integy, Jamara, JQ Products, Kawada, Kyosho, Losi, LRP, Maisto, Mardave, Marui, Maverick, MCD Racing, Megatech, Mugen, New Bright, Nichimo, Nikko, Nkok, Ofna, Pro-Pulse, Protech, PTI, RC4WD, Redcat Racing, RJ-Speed, Robitronic, Schumacher, Seben, Serpent, Smartech, Sportwerks, Step-Up, Tamiya, Team-C Racing, Team Magic, Thunder Tiger, Tomy, Top Racing, Traxxas, Trinity, Tyco, Vaterra RC, Venom, VRX Racing, WLToys, X-Factory, Xmods, Xpress, Xray, XTM, Yankee RC, Yokomo, ZD Racing and Zipzaps. |

|

Hints, Tips and Information

Slipper Clutch and Hydra-Drive

More often installed on Off-Road RC Models, the Slipper Clutch has been around since the late 1990s. Basically the idea is to prevent wheel spin and increase traction under acceleration, to improve the cars stability from a standing start, when landing from jumps or on corner exits. It also protects the spur gear and drivetrain, to some degree, when using a high torque motor. |

|

Hints, Tips and Information

Soldering Battery Packs

Nicad and Nimh batteries sometimes come as six separate matched 1.2 volt cells. These of course have to be soldered to each other in series to produce either a side by side stick pack, or a two times three cell saddle pack.

|

|

RC Models:

|

Radio & Motors: |

Other

Accessories: |