|

|

|

1/10 Scale Nitro Rally/Touring Car:

Kyosho V-One S II

|

Released by Kyosho in 2003, the PureTen V-One SII was available in a number of kits, including - # 31121 G'ZOX Mugan NSX - # 31122 ESSO Ultraflo Supra - # 31123 Nismo Fairlady 350Z - # 31124 Alfa 15 GTA Super 2000 - # 31125 CLK DTM 2002 AMG Mercedes - # 31126 Plus e Taisan Advan.

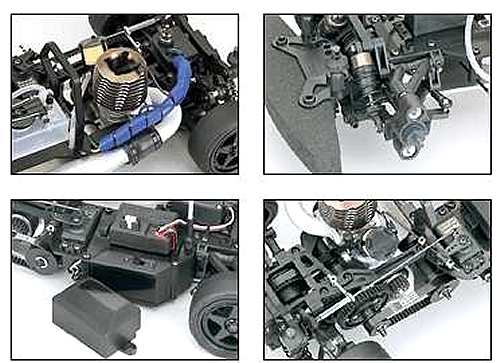

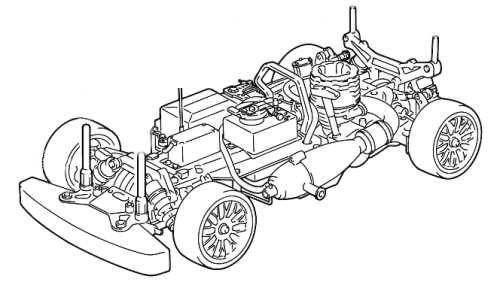

The belt driven, alloy plate chassis, has gear type differentials, coil spring over oil filled dampers, dogbone drive-shafts, a full set of ball bearings and GS15-R engine.

Check out our Kyosho Archive for other Vintage Car models.

To race the Kyosho V-One S II, it has to have the best settings for your driving style and provide you with excellent handling and stability. The smallest changes can make a huge difference in the way your car performs on the track and our comprehensive instructions will help you to find the best Set-up to get you where you want to be.

|

|

|

★ Kyosho V-One SII Chassis ★

★ Kyosho V-One SII Chassis ★

|

Buying a Used Kyosho V-One S II

|

|

Manufacturers and Brands Catalogued, Listed and Reviewed by RC-Scrapyard.

At present, the RC Model Manufacturers, Brands and Distributors covered by us are: ABC Hobby, Academy, Acme Racing, Agama Racing, Amewi, Ansmann Racing, ARRMA, Team Associated, Atomic RC, Axial, AYK, Bolink, BSD Racing, Capricorn, Carisma, Carson, Caster Racing, Cen, Corally, Custom Works, Durango, Duratrax, ECX - Electrix, Exceed RC, FG Modellsport, FS-Racing, FTX, Fujimi, Gmade, GS-Racing, Harm, HBX, Helion, Heng Long, Himoto Racing, Hirobo, Hitari, Hobao, Hong-Nor, Hot Bodies, HPI, HSP, Intech, Integy, Jamara, JQ Products, Kawada, Kyosho, Losi, LRP, Maisto, Mardave, Marui, Maverick, MCD Racing, Megatech, Mugen, New Bright, Nichimo, Nikko, Nkok, Ofna, Pro-Pulse, Protech, PTI, RC4WD, Redcat Racing, RJ-Speed, Robitronic, Schumacher, Seben, Serpent, Smartech, Sportwerks, Step-Up, Tamiya, Team-C Racing, Team Magic, Thunder Tiger, Tomy, Top Racing, Traxxas, Trinity, Tyco, Vaterra RC, Venom, VRX Racing, WLToys, X-Factory, Xmods, Xpress, Xray, XTM, Yankee RC, Yokomo, ZD Racing and Zipzaps. |

|

Hints, Tips and Information

Ride Height

To allow the suspension on any RC model to do its work properly, it needs to ride in a position where it is able to react to any bumps and holes it may encounter on the track. Therefore, it needs to be adjusted to somewhere in-between those limits. That position is commonly termed "ground clearance" or "ride height" and is generally measured as the distance between the underside of the chassis and the ground, with the motor and battery etc installed. |

|

Hints, Tips and Information

Keeping Notes

If all you will ever do is go racing at your local track every week, then this article is not for you. However, if you ever look towards travelling around to different tracks around the country, or even the world, the value of keeping notes is all too obvious.

|

|

RC Models:

|

Radio & Motors: |

Other

Accessories: |