|

|

|

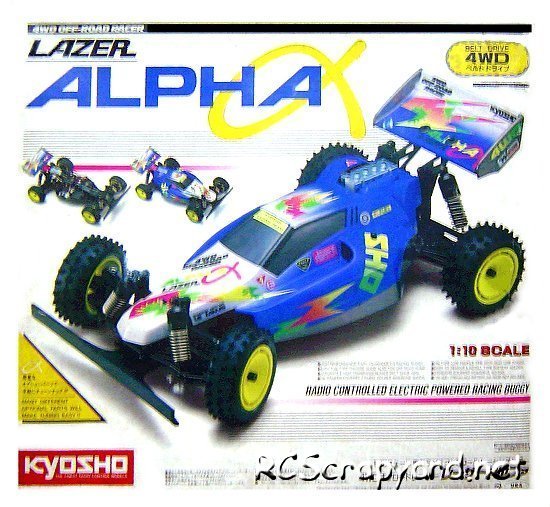

1/10 Scale Electric Buggy:

Kyosho Lazer Alpha - 3036

|

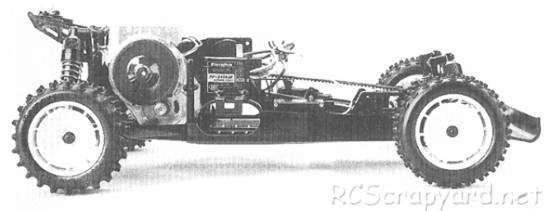

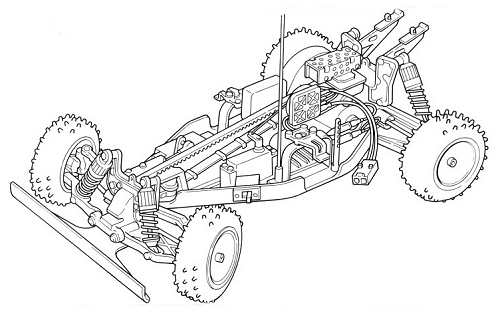

Released by Kyosho in 1992, the Lazer Alpha - # 3036 - 4WD off-road racer, is belt driven, with a molded plastic chassis, gear type differentials, coil spring over oil filled dampers, front and rear dogbone drive-shafts, metal ring type bearings and came with a 540 electric motor and mechanical speed controller.

Check out our Kyosho Archive for other Vintage models.

To race the Kyosho Lazer Alpha, you need to tweak and adjust all you can to give your car improved handling, stability and grip to ease around the curves and keep you on the track. One little setting change can transform your car into a world beater. Just follow our chart to attain the most favourable Set-up to suit your particular needs on any track.

|

|

|

★ Kyosho Lazer Alpha - 3036 ★

★ Kyosho Lazer Alpha - 3036 ★

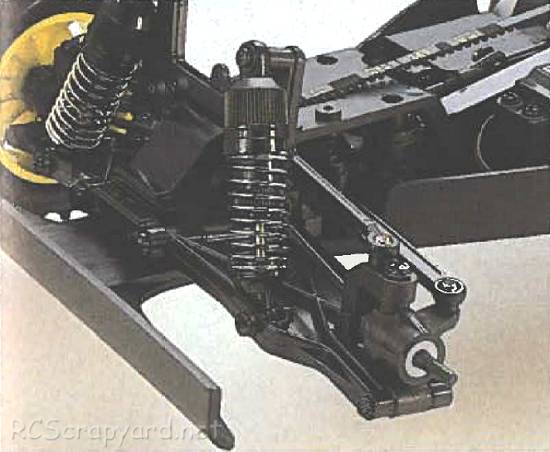

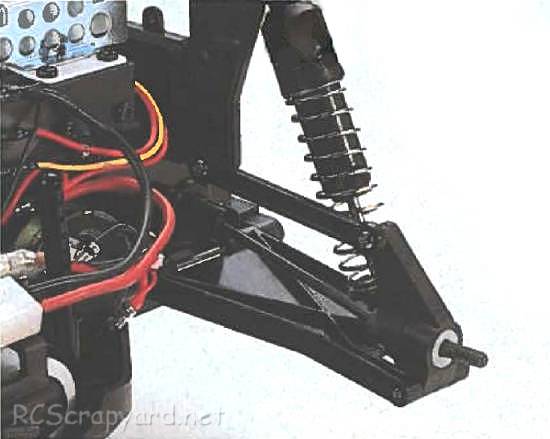

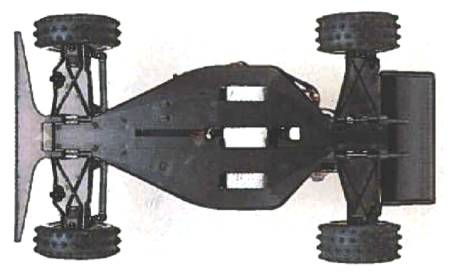

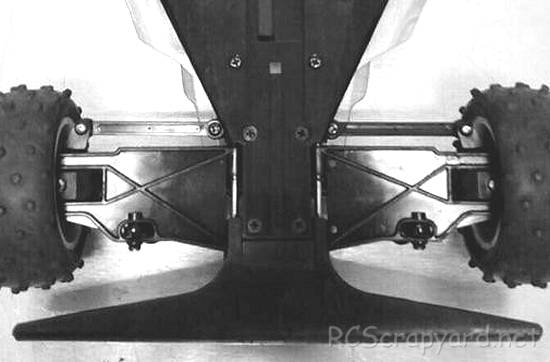

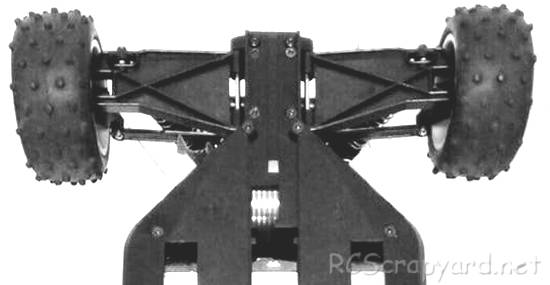

★ Kyosho Lazer Alpha - 3036 - Chassis ★

★ Kyosho Lazer Alpha - 3036 - Chassis ★

★ Kyosho Lazer Alpha - 3036 - Chassis ★

★ Kyosho Lazer Alpha - 3036 - Chassis ★

★ Kyosho Lazer Alpha - 3036 - Chassis ★

★ Kyosho Lazer Alpha - 3036 - Chassis ★

★ Kyosho Lazer Alpha - 3036 - Chassis ★

★ Kyosho Lazer Alpha - 3036 - Chassis ★

★ Kyosho Lazer Alpha - 3036 - Chassis ★

★ Kyosho Lazer Alpha Chassis ★

|

Buying a Used Kyosho Lazer Alpha Buggy (and What to look for)

Make a General Visual Inspection

Check the Body-Shell

If the body shell of your Kyosho Lazer Alpha is broken, ripped or damaged in any way, this can be easily repaired with rubber solution glue. Also, for added protection and if available for your Lazer Alpha model, fit an under guard to stop dirt and gravel entering the chassis. Drive Shafts and Turnbuckles

Examine the Drive System

Drive Belts need checking at regular intervals for wear, tension and damage. If deemed necessary, adjust the tensioning pulley until the belt can be depressed in the centre by no more than around 5mm. If the belt was slack, also examine the drive pulleys for wear. The teeth should provide a well seated fit for the belt teeth and not be rounded on the corners. If the belt teeth do not fit snugly, change the pulleys as soon as possible. For top level racing it may be prudent to replace all belts and pulleys after each race meeting. Pinions and Spur Gears

Don't Neglect the Ball-Joints

Ball joints always cause problems. For top level Electric Buggy racing, the plastic ball connectors should be checked and if deemed necessary changed after every meeting. A simple thing like a loose fitting connector popping off could easily end your race, so better safe than sorry. Steering Servo and Servo-Saver

Stabilizers

If body roll on your Kyosho Lazer Alpha is a problem, handling can be improved with the use of stabilizers, anti roll or sway bars, stiffer tuning springs and, or, thicker silicone oil in the dampers. Don't Forget those Bearings

▼ Scroll Down for More Articles and Advice ▼

Or, check out our RC Model Car Setup Guide

|

|

Manufacturers and Brands Catalogued, Listed and Reviewed by RC-Scrapyard.

At present, the RC Model Manufacturers, Brands and Distributors covered by us are: ABC Hobby, Academy, Acme Racing, Agama Racing, Amewi, Ansmann Racing, ARRMA, Team Associated, Atomic RC, Axial, AYK, Bolink, BSD Racing, Capricorn, Carisma, Carson, Caster Racing, Cen, Corally, Custom Works, Durango, Duratrax, ECX - Electrix, Exceed RC, FG Modellsport, FS-Racing, FTX, Fujimi, Gmade, GS-Racing, Harm, HBX, Helion, Heng Long, Himoto Racing, Hirobo, Hitari, Hobao, Hong-Nor, Hot Bodies, HPI, HSP, Intech, Integy, Jamara, JQ Products, Kawada, Kyosho, Losi, LRP, Maisto, Mardave, Marui, Maverick, MCD Racing, Megatech, Mugen, New Bright, Nichimo, Nikko, Nkok, Ofna, Pro-Pulse, Protech, PTI, RC4WD, Redcat Racing, RJ-Speed, Robitronic, Schumacher, Seben, Serpent, Smartech, Sportwerks, Step-Up, Tamiya, Team-C Racing, Team Magic, Thunder Tiger, Tomy, Top Racing, Traxxas, Trinity, Tyco, Vaterra RC, Venom, VRX Racing, WLToys, X-Factory, Xmods, Xpress, Xray, XTM, Yankee RC, Yokomo, ZD Racing and Zipzaps. |

|

Hints, Tips and Information

Anti Squat

Described as the angle at which the suspension arms pivot in relation to the chassis, Anti Squat affects traction under acceleration. |

|

Hints, Tips and Information

Rubber Tires for RC Models

Rubber Tires ALWAYS should have either soft sponge or rubber inserts. They will not function as they should without them. And if you are totally serious about your racing they should be glued to the rims. How to Mount Rubber Tires onto Wheels/Rims.

Before mounting your Tires, I would recommend talking to the more experienced racers at your local club, concerning what inserts they use. Even the top level racers rely on a bit of local knowledge on tracks they have never raced before. |

|

RC Models:

|

Radio & Motors: |

Other

Accessories: |