|

|

|

1/10 Scale Electric Buggy:

Kyosho DBX VE 2.0 - 30845

|

Released by Kyosho in 2011, the 4WD DBX VE 2.0 ReadySet Buggy - # 30845 - is shaft driven, on a formed plate chassis, with gear differentials, coil spring over oil filled dampers, dogbone drive-shafts and a full set of ball bearings.

This model was released in September 2016, ReadySet with a KT-231P Transmitter - # 34201T2.

To race the Kyosho DBX VE 2.0, it calls for fine tuning to attain better steering response and improve grip when cornering so you don't slide off the side of the track. Minute changes can make huge advancements. Our easy to understand list will show you how and lead you to the optimum Set-up to put you in front of the rest on the track.

|

|

|

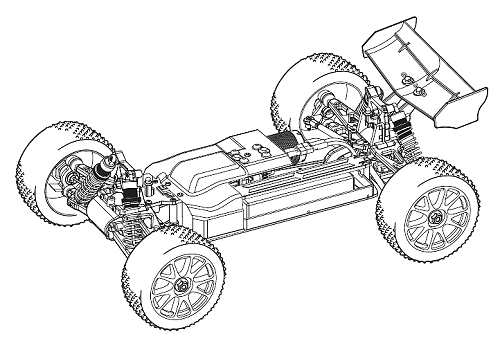

★ Kyosho DBX VE 2.0 - 30845 Chassis ★

★ Kyosho DBX VE 2.0 - 30845 Chassis ★

★ Kyosho DBX VE 2.0 - 30845 ★

|

Buying a Used Kyosho DBX VE 2.0 Buggy (and What to look for)

Make a General Visual Inspection

Check the Body-Shell

If the body shell of your Kyosho DBX VE 2.0 is broken, ripped or damaged in any way, this can be easily repaired with rubber solution glue. Also, for added protection and if available for your DBX VE 2.0 model, fit an under guard to stop dirt and gravel entering the chassis. Drive Shafts and Turnbuckles

Examine the Drive System

The gearbox of your used Buggy should be opened up to check for gear wear and lubrication. A thin coat of grease is often used on internal gears and although this is fine for basic running around on the back yard, if you intend to race your Buggy at a higher level, this should be removed and replaced with racing oil (ZX1 or Teflon Oil). Of course, this should be reapplied after each race meeting. Pinions and Spur Gears

Don't Neglect the Ball-Joints

Ball joints always cause problems. For top level Electric Buggy racing, the plastic ball connectors should be checked and if deemed necessary changed after every meeting. A simple thing like a loose fitting connector popping off could easily end your race, so better safe than sorry. Steering Servo and Servo-Saver

Stabilizers

If body roll on your Kyosho DBX VE 2.0 is a problem, handling can be improved with the use of stabilizers, anti roll or sway bars, stiffer tuning springs and, or, thicker silicone oil in the dampers. Don't Forget those Bearings

▼ Scroll Down for More Articles and Advice ▼

Or, check out our RC Model Car Setup Guide

|

|

Manufacturers and Brands Catalogued, Listed and Reviewed by RC-Scrapyard.

At present, the RC Model Manufacturers, Brands and Distributors covered by us are: ABC Hobby, Academy, Acme Racing, Agama Racing, Amewi, Ansmann Racing, ARRMA, Team Associated, Atomic RC, Axial, AYK, Bolink, BSD Racing, Capricorn, Carisma, Carson, Caster Racing, Cen, Corally, Custom Works, Durango, Duratrax, ECX - Electrix, Exceed RC, FG Modellsport, FS-Racing, FTX, Fujimi, Gmade, GS-Racing, Harm, HBX, Helion, Heng Long, Himoto Racing, Hirobo, Hitari, Hobao, Hong-Nor, Hot Bodies, HPI, HSP, Intech, Integy, Jamara, JQ Products, Kawada, Kyosho, Losi, LRP, Maisto, Mardave, Marui, Maverick, MCD Racing, Megatech, Mugen, New Bright, Nichimo, Nikko, Nkok, Ofna, Pro-Pulse, Protech, PTI, RC4WD, Redcat Racing, RJ-Speed, Robitronic, Schumacher, Seben, Serpent, Smartech, Sportwerks, Step-Up, Tamiya, Team-C Racing, Team Magic, Thunder Tiger, Tomy, Top Racing, Traxxas, Trinity, Tyco, Vaterra RC, Venom, VRX Racing, WLToys, X-Factory, Xmods, Xpress, Xray, XTM, Yankee RC, Yokomo, ZD Racing and Zipzaps. |

Information and AdviceElectronic Speed ControllersHistory

ESC were originally developed to be used in conjunction with brushed 27T stock and modified motors in the late 1970s, early 1980s. Compared to modern day Controllers, they were Bulky and heavy, constructed using basic resistors, rheostats, capacitors and transistors, crammed together on a simple circuit board, to provide stepped but smooth acceleration when compared to the old mechanical, servo operated sweeper Speed Controllers. An Electronic Switch to change the direction of current flow was used on some of these early ESC to give reverse operation. Although they were a vast improvement on the old mechanical speedos of the time, they were expensive, jerky to control, and prone to burn out if not carefully looked after. |

|

Hints, Tips and Information

Radio Frequencies - be Careful be Safe

After buying your first car, it won't be long before you need more than simply bashing around the back yard, or out on the street. So you will be looking around to find a club that is not too far away where you can do some serious racing. |

|

RC Models:

|

Radio & Motors: |

Other

Accessories: |