|

|

|

|

|

1/5 Scale Nitro Monster Truck:

HPI Maverick Blackout MT - # MV12401 - Radio Controlled ModelHistory and Info for the HPI Maverick Blackout MT:

First distributed by HPI Racing circa 2011, the 4WD Maverick Blackout MT Monster Truck - # MV12401 - was later replaced by - # MV12404 - and came RTR with a 30cc engine and 2.4Ghz radio system.

▼ Scroll Down for More Images ▼

|

|

|

|

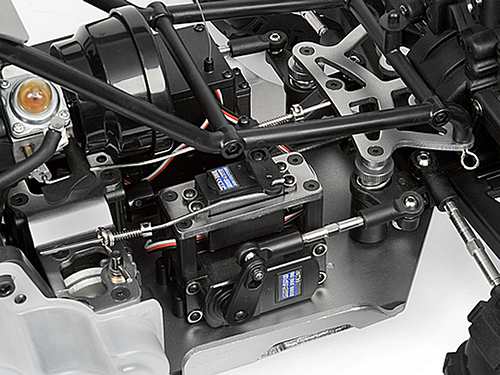

★ HPI Racing Maverick Blackout MT Chassis ★

★ HPI Racing Maverick Blackout MT Chassis ★

|

Buying a Used HPI Maverick Blackout MT

|

|

Manufacturers and Brands Catalogued, Listed and Reviewed by RC-Scrapyard.

At present, the RC Model Manufacturers, Brands and Distributors covered by us are: ABC Hobby, Academy, Acme Racing, Agama Racing, Amewi, Ansmann Racing, ARRMA, Team Associated, Atomic RC, Axial, AYK, Bolink, BSD Racing, Capricorn, Carisma, Carson, Caster Racing, Cen, Corally, Custom Works, Durango, Duratrax, ECX - Electrix, Exceed RC, FG Modellsport, FS-Racing, FTX, Fujimi, Gmade, GS-Racing, Harm, HBX, Helion, Heng Long, Himoto Racing, Hirobo, Hitari, Hobao, Hong-Nor, Hot Bodies, HPI, HSP, Intech, Integy, Jamara, JQ Products, Kawada, Kyosho, Losi, LRP, Maisto, Mardave, Marui, Maverick, MCD Racing, Megatech, Mugen, New Bright, Nichimo, Nikko, Nkok, Ofna, Pro-Pulse, Protech, PTI, RC4WD, Redcat Racing, RJ-Speed, Robitronic, Schumacher, Seben, Serpent, Smartech, Sportwerks, Step-Up, Tamiya, Team-C Racing, Team Magic, Thunder Tiger, Tomy, Top Racing, Traxxas, Trinity, Tyco, Vaterra RC, Venom, VRX Racing, WLToys, X-Factory, Xmods, Xpress, Xray, XTM, Yankee RC, Yokomo, ZD Racing and Zipzaps. |

|

Hints, Tips and Information Make your RC Model Ball Bearings Work for You

If you are serious about your racing, looking after your bearings is essential if you are to remain competitive. |

|

Hints, Tips and Information

Toe Angle - for Steering and Straight Line Stability

When you first build your RC model car, you will no doubt have made all the settings advised in the manufacturers' manual and will take it out on the back yard not thinking of things like camber, caster or toe-in - I know I did. It's only when you get competitive that you start learning about these things and just what a big difference they can make to the handling of your car. One of the more effective of these adjustments is Toe-in. |

|

RC Models:

|

Radio & Motors: |

Other

Accessories: |