|

|

|

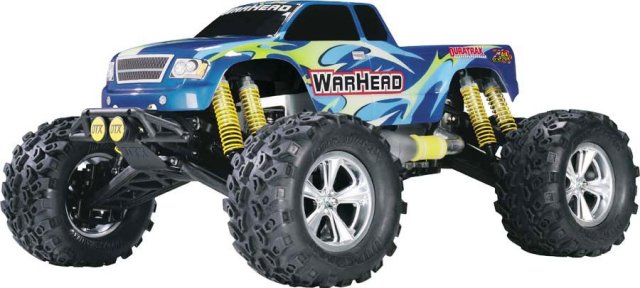

1/8 Scale Nitro Monster Truck:

Duratrax Warhead - DTXD68**

|

Introduced by Duratrax in 2004, the 4WD Warhead Monster Truck, was available RTR - DTXD68** - with a Super Tigre G-27CX 4.4cc engine and Futaba radio system.

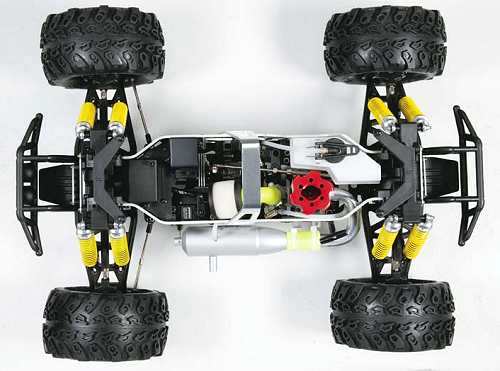

The model is shaft driven, on a vertical alloy plate chassis, with gear type differentials, 8 x coil spring over oil filled dampers, CV universal joint drive-shafts, 2-Speed forward and reverse transmission and a full set of ball bearings.

To race the Duratrax Warhead, it needs to be tuned to perfection for better stability, precise steering and provide enough grip to keep you on the track when going around tight bends at high speed. Even the smallest adjustment can change the feel of a car and our simple to follow instructions will guide you to the best Set-up to get you to the front and keep you there.

|

|

|

★ Duratrax Warhead ★

★ Duratrax Warhead ★

★ Duratrax Warhead Chassis ★

★ Duratrax Warhead Chassis ★

|

Buying a Used Duratrax Warhead

|

|

Manufacturers and Brands Catalogued, Listed and Reviewed by RC-Scrapyard.

At present, the RC Model Manufacturers, Brands and Distributors covered by us are: ABC Hobby, Academy, Acme Racing, Agama Racing, Amewi, Ansmann Racing, ARRMA, Team Associated, Atomic RC, Axial, AYK, Bolink, BSD Racing, Capricorn, Carisma, Carson, Caster Racing, Cen, Corally, Custom Works, Durango, Duratrax, ECX - Electrix, Exceed RC, FG Modellsport, FS-Racing, FTX, Fujimi, Gmade, GS-Racing, Harm, HBX, Helion, Heng Long, Himoto Racing, Hirobo, Hitari, Hobao, Hong-Nor, Hot Bodies, HPI, HSP, Intech, Integy, Jamara, JQ Products, Kawada, Kyosho, Losi, LRP, Maisto, Mardave, Marui, Maverick, MCD Racing, Megatech, Mugen, New Bright, Nichimo, Nikko, Nkok, Ofna, Pro-Pulse, Protech, PTI, RC4WD, Redcat Racing, RJ-Speed, Robitronic, Schumacher, Seben, Serpent, Smartech, Sportwerks, Step-Up, Tamiya, Team-C Racing, Team Magic, Thunder Tiger, Tomy, Top Racing, Traxxas, Trinity, Tyco, Vaterra RC, Venom, VRX Racing, WLToys, X-Factory, Xmods, Xpress, Xray, XTM, Yankee RC, Yokomo, ZD Racing and Zipzaps. |

|

Hints, Tips and Information

The Importance of Suspension Droop

When you pick up your RC model car, the suspension arms naturally drop, this is termed as Droop and should be equal from side to side, but can vary from front to rear. |

|

Hints, Tips and Information

Tires for RC ModelsSponge (Foam) Tires

Sponge Tires can be purchased either pre mounted, glued and trued on the rims, or separately. Fitting the Tires onto the rims can be messy, so here are a few tips to make it a bit easier.

|

|

RC Models:

|

Radio & Motors: |

Other

Accessories: |