|

|

|

1/10 Scale Electric Buggy:

Bolink Digger-10

|

Introduced by Bolink circa 1982, the Digger 10 was basically the Bolink Round Tracker with Buggy wheels, imported and distributed around the UK and Europe by Schumacher, who in fact provided the ball differential for the model.

The Digger 10 took a number of its components from the Bolink Challenger, which itself had taken parts from other manufacturers, (check out our Challenger page).

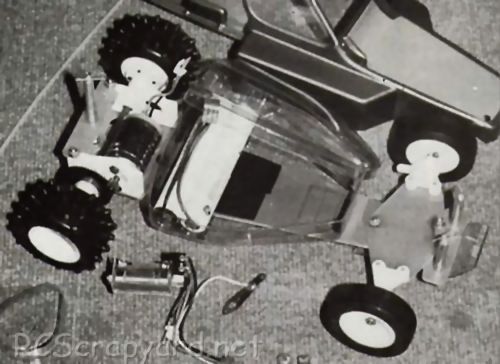

The model is based on an FRP plate chassis, with a second radio plate deck and two smaller cross plates bolted on at the front and rear to provide a base for the plastic steering blocks and motor/axle mounts respectively, each resting on rubber grommets to provide some kind of suspension flexure. A steel drive-shaft with a ball differential completes the assembly.

|

|

|

★ Bolink Digger-10 Chassis ★

★ Bolink Digger-10 Chassis ★

★ Bolink Digger-10 Chassis ★

|

Buying a Used Bolink Digger-10

|

|

Manufacturers and Brands Catalogued, Listed and Reviewed by RC-Scrapyard.

At present, the RC Model Manufacturers, Brands and Distributors covered by us are: ABC Hobby, Academy, Acme Racing, Agama Racing, Amewi, Ansmann Racing, ARRMA, Team Associated, Atomic RC, Axial, AYK, Bolink, BSD Racing, Capricorn, Carisma, Carson, Caster Racing, Cen, Corally, Custom Works, Durango, Duratrax, ECX - Electrix, Exceed RC, FG Modellsport, FS-Racing, FTX, Fujimi, Gmade, GS-Racing, Harm, HBX, Helion, Heng Long, Himoto Racing, Hirobo, Hitari, Hobao, Hong-Nor, Hot Bodies, HPI, HSP, Intech, Integy, Jamara, JQ Products, Kawada, Kyosho, Losi, LRP, Maisto, Mardave, Marui, Maverick, MCD Racing, Megatech, Mugen, New Bright, Nichimo, Nikko, Nkok, Ofna, Pro-Pulse, Protech, PTI, RC4WD, Redcat Racing, RJ-Speed, Robitronic, Schumacher, Seben, Serpent, Smartech, Sportwerks, Step-Up, Tamiya, Team-C Racing, Team Magic, Thunder Tiger, Tomy, Top Racing, Traxxas, Trinity, Tyco, Vaterra RC, Venom, VRX Racing, WLToys, X-Factory, Xmods, Xpress, Xray, XTM, Yankee RC, Yokomo, ZD Racing and Zipzaps. |

|

Hints, Tips and Information

Wheel Camber - for cornering stability

Camber is described as the angle of the wheel as you look at it directly from the front or rear of your car and if set correctly will improve your cars cornering ability considerably, by providing increased traction. This simple to make adjustment is considered by many to be one of the most effective changes you can make to your car for better handling. |

|

Hints, Tips and Information

Your First Race Meeting

When you finally find a racing club near to where you live, that initial experience of stepping up onto the rostrum and looking down over the track can be very daunting. But soon, as the race starts, adrenaline will kick in and away you go. For the next five minutes, your focus is on nothing but getting your car around each corner, avoiding all the other cars on the track and just getting to the end of the race. |

|

RC Models:

|

Radio & Motors: |

Other

Accessories: |