|

|

|

1/10 Scale Electric Rally/Touring Car:

Team Associated Apex Scion Racing tC - 30114 / 30114D / 30114C / 30114DC

|

Introduced by Team Associated in 2014, the Apex Scion Racing tC Touring Car - # 30114 - and Drift version - # 30114D - with hard plastic drift-style tires, were "Qualifier Series" models and came RTR with a Reedy 3300kV 540 Brushless Motor, Water-resistant ESC, Reedy WolfPack 6-cell NiMh Battery, Wall Charger and 2.4Ghz Radio System.

In 2015 two Apex Scion Racing tC Combo RTR models were introduced: A Touring Car version - # 30114C - and a Drift version - # 30114DC -, both with a Reedy 3300kV 540 Brushless Motor, XP ESC, LiPo Battery, Reedy 324-S Compact Balance Charger and XP 2.4Ghz Radio System.

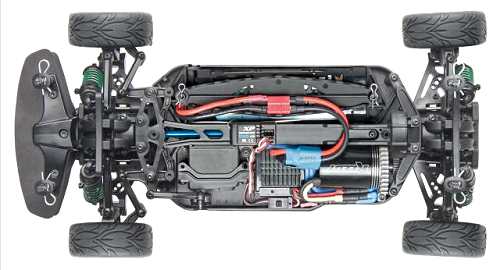

The Apex 4WD chassis is shaft driven, with gear differentials, coil spring over oil filled dampers, universal joint (CVA) drive shafts, a full set of ball bearings and 5 spoke wheels.

The Fixed length steering and camber links on this model, can easily be replaced by turnbuckles to increase adjustability for fine tuning.

To race the Team Associated Apex Scion Racing tC, it calls for fine tuning to attain better steering response and improve grip when cornering so you don't slide off the side of the track. Minute changes can make huge advancements. Our easy to understand list will show you how and lead you to the optimum Set-up to put you in front of the rest on the track.

|

|

|

★ Team Associated Apex Scion Racing tC - 30114 Chassis ★

★ Team Associated Apex Scion Racing tC - 30114 Chassis ★

★ Team Associated Apex Scion Racing tC - 30114 Chassis ★

★ Team Associated Apex Scion Racing tC - 30114 Chassis ★

★ Team Associated Apex Scion Racing tC - 30114 Chassis ★

|

Buying a Used Team Associated Apex Scion Racing tC

|

|

Manufacturers and Brands Catalogued, Listed and Reviewed by RC-Scrapyard.

At present, the RC Model Manufacturers, Brands and Distributors covered by us are: ABC Hobby, Academy, Acme Racing, Agama Racing, Amewi, Ansmann Racing, ARRMA, Team Associated, Atomic RC, Axial, AYK, Bolink, BSD Racing, Capricorn, Carisma, Carson, Caster Racing, Cen, Corally, Custom Works, Durango, Duratrax, ECX - Electrix, Exceed RC, FG Modellsport, FS-Racing, FTX, Fujimi, Gmade, GS-Racing, Harm, HBX, Helion, Heng Long, Himoto Racing, Hirobo, Hitari, Hobao, Hong-Nor, Hot Bodies, HPI, HSP, Intech, Integy, Jamara, JQ Products, Kawada, Kyosho, Losi, LRP, Maisto, Mardave, Marui, Maverick, MCD Racing, Megatech, Mugen, New Bright, Nichimo, Nikko, Nkok, Ofna, Pro-Pulse, Protech, PTI, RC4WD, Redcat Racing, RJ-Speed, Robitronic, Schumacher, Seben, Serpent, Smartech, Sportwerks, Step-Up, Tamiya, Team-C Racing, Team Magic, Thunder Tiger, Tomy, Top Racing, Traxxas, Trinity, Tyco, Vaterra RC, Venom, VRX Racing, WLToys, X-Factory, Xmods, Xpress, Xray, XTM, Yankee RC, Yokomo, ZD Racing and Zipzaps. |

Information and AdviceElectronic Speed ControllersHistory

ESC were originally developed to be used in conjunction with brushed 27T stock and modified motors in the late 1970s, early 1980s. Compared to modern day Controllers, they were Bulky and heavy, constructed using basic resistors, rheostats, capacitors and transistors, crammed together on a simple circuit board, to provide stepped but smooth acceleration when compared to the old mechanical, servo operated sweeper Speed Controllers. An Electronic Switch to change the direction of current flow was used on some of these early ESC to give reverse operation. Although they were a vast improvement on the old mechanical speedos of the time, they were expensive, jerky to control, and prone to burn out if not carefully looked after. |

|

Hints, Tips and Information

Wheel Camber - for cornering stability

Camber is described as the angle of the wheel as you look at it directly from the front or rear of your car and if set correctly will improve your cars cornering ability considerably, by providing increased traction. This simple to make adjustment is considered by many to be one of the most effective changes you can make to your car for better handling. |

|

RC Models:

|

Radio & Motors: |

Other

Accessories: |