|

|

|

1/10 Scale Nitro Buggy:

Acme Racing Condor

|

Introduced by Acme Racing circa 2003, the 4WD Condor Buggy Chassis was available with a number of bodyshell options, as a ready to assemble kit - # A3001 - or pre-assembled, RTR - # A3001T - with an engine (early versions .15, later .18) and radio system.

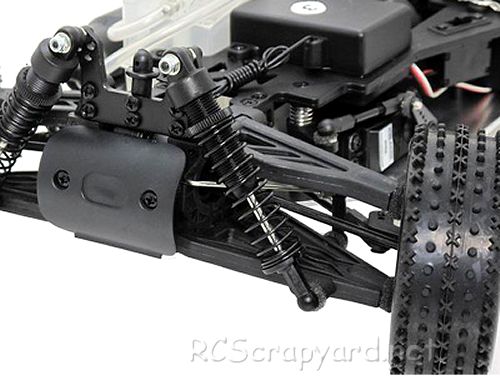

The model is shaft driven, on an alloy plate chassis, with gear type differentials, coil spring over oil filled dampers, dogbone drive-shafts, anti-roll bars, disc brake system and bushings.

To race the Acme Condor, it requires time and patience, to tune and adjust for improvements in handling and steering ability and to get the grip you need to stay on course when manoeuvring around tight, slippery corners. A little can be a lot when it comes to changing your cars settings and our easy methodical directions will guide you to the best Set-up to help you win and keep you winning.

|

|

|

★ Acme Racing Condor Chassis ★

★ Acme Racing Condor Chassis ★

★ Acme Racing Condor Chassis ★

|

Buying a Used Acme Racing Condor

|

|

Manufacturers and Brands Catalogued, Listed and Reviewed by RC-Scrapyard.

At present, the RC Model Manufacturers, Brands and Distributors covered by us are: ABC Hobby, Academy, Acme Racing, Agama Racing, Amewi, Ansmann Racing, ARRMA, Team Associated, Atomic RC, Axial, AYK, Bolink, BSD Racing, Capricorn, Carisma, Carson, Caster Racing, Cen, Corally, Custom Works, Durango, Duratrax, ECX - Electrix, Exceed RC, FG Modellsport, FS-Racing, FTX, Fujimi, Gmade, GS-Racing, Harm, HBX, Helion, Heng Long, Himoto Racing, Hirobo, Hitari, Hobao, Hong-Nor, Hot Bodies, HPI, HSP, Intech, Integy, Jamara, JQ Products, Kawada, Kyosho, Losi, LRP, Maisto, Mardave, Marui, Maverick, MCD Racing, Megatech, Mugen, New Bright, Nichimo, Nikko, Nkok, Ofna, Pro-Pulse, Protech, PTI, RC4WD, Redcat Racing, RJ-Speed, Robitronic, Schumacher, Seben, Serpent, Smartech, Sportwerks, Step-Up, Tamiya, Team-C Racing, Team Magic, Thunder Tiger, Tomy, Top Racing, Traxxas, Trinity, Tyco, Vaterra RC, Venom, VRX Racing, WLToys, X-Factory, Xmods, Xpress, Xray, XTM, Yankee RC, Yokomo, ZD Racing and Zipzaps. |

|

Hints, Tips and Information

Choosing a Nitro Engine.

Once you have made your choice of RC model, you need the right engine to get you where you want to be - out in front.

|

|

Hints, Tips and Information

Rubber Tires for RC Models

Rubber Tires ALWAYS should have either soft sponge or rubber inserts. They will not function as they should without them. And if you are totally serious about your racing they should be glued to the rims. How to Mount Rubber Tires onto Wheels/Rims.

Before mounting your Tires, I would recommend talking to the more experienced racers at your local club, concerning what inserts they use. Even the top level racers rely on a bit of local knowledge on tracks they have never raced before. |

|

RC Models:

|

Radio & Motors: |

Other

Accessories: |