|

|

|

|

|

1/12 Scale Electric Rock Crawler:

ECX Barrage Gen2 1.55 Class 4WD - ECX01013T2

|

Introduced by ECX circa 2018, the Barrage Gen2 1.55 4WD Scaler Rock Crawler - ECX01013T2 / ECX01013IT2 - came RTR with a Dynamite Tazer 390 Brushed Motor, 60A ESC, Dynamite 900Mah Ni-MH Battery, Charger, 2.4Ghz Radio System and a Pre-Painted Yellow Bodyshell (Specifications may vary from country to country).

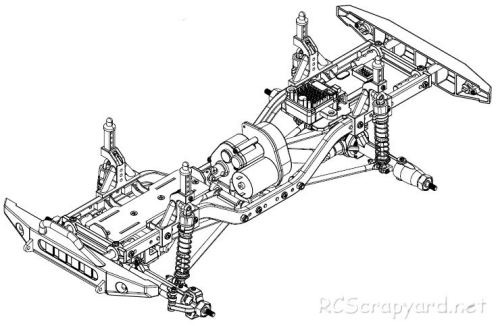

The plastic telescopic UJ shaft driven 4WD model is based on a steel ladder frame chassis, with locked differentials, front universal joint drive-shafts, multi link suspension, coil spring over oil filled dampers and ball bearings.

|

|

|

★ ECX Barrage Gen2 1.55 Class 4WD - ECX01013T2 Rock Crawler ★

★ ECX Barrage Gen2 1.55 Class 4WD - ECX01013T2 Rock Crawler Chassis ★

★ ECX Barrage Gen2 1.55 Class 4WD - ECX01013T2 Rock Crawler Chassis ★

★ ECX Barrage Gen2 1.55 Class 4WD - ECX01013T2 Rock Crawler ★

★ ECX Barrage Gen2 1.55 Class 4WD - ECX01013T2 Rock Crawler Chassis ★

★ ECX Barrage Gen2 1.55 Class 4WD - ECX01013T2 Rock Crawler Chassis ★

★ ECX Barrage Gen2 1.55 Class 4WD - ECX01013T2 Rock Crawler Chassis ★

★ ECX Barrage Gen2 1.55 Class 4WD - ECX01013T2 Rock Crawler ★

★ ECX Barrage Gen2 1.55 Class 4WD - ECX01013T2 Rock Crawler Chassis ★

★ ECX Barrage Gen2 1.55 Class 4WD - ECX01013T2 Rock Crawler ★

|

Buying a Used ECX Rock Crawler (and What to look for)

Make a General Visual Inspection

Check the Body-Shell

If the body shell of your Rock Crawler is broken, ripped or damaged in any way, this can be easily repaired with rubber solution glue. Also, for added protection and if available for your model, fit an under guard to stop dirt and gravel entering the chassis. Drive Shafts and Turnbuckles

Examine the Drive System

The gearbox of your used Rock Crawler should be opened up to check for damaged gears and wear. If there is excessive backlash in the gearing, these should be replaced. A thin coat of grease on the gears is enough to allow smooth operation and reduce further wear. Pinions and Spur Gears

Steering Servo and Servo-Saver

Don't Forget those Bearings

|

|

Manufacturers and Brands Catalogued and Listed by RC-Scrapyard.

At present, the RC Model Manufacturers, Brands and Distributors covered by us are: ABC Hobby, Academy, Acme Racing, Agama Racing, Amewi, Ansmann Racing, ARRMA, Team Associated, Atomic RC, Axial, AYK, Bolink, ECX, Capricorn, Carisma, Carson, Caster Racing, Cen, Corally, Custom Works, Durango, Duratrax, ECX - Electrix, Exceed RC, FG Modellsport, FS-Racing, FTX, Fujimi, Gmade, GS-Racing, Harm, HBX, Helion, Heng Long, Himoto Racing, Hirobo, Hitari, Hobao, Hong-Nor, Hot Bodies, HPI, HSP, Intech, Integy, Jamara, JQ Products, Kawada, Kyosho, Losi, LRP, Maisto, Mardave, Marui, Maverick, MCD Racing, Megatech, Mugen, New Bright, Nichimo, Nikko, Nkok, Ofna, Pro-Pulse, Protech, PTI, RC4WD, Redcat Racing, RJ-Speed, Robitronic, Schumacher, Seben, Serpent, Smartech, Sportwerks, Step-Up, Tamiya, Team-C Racing, Team Magic, Thunder Tiger, Tomy, Top Racing, Traxxas, Trinity, Tyco, Vaterra RC, Venom, VRX Racing, WLToys, X-Factory, Xmods, Xpress, Xray, XTM, Yankee RC, Yokomo, ZD Racing and Zipzaps. |

|

Hints, Tips and Information

Wheel Camber - for cornering stability

Camber is described as the angle of the wheel as you look at it directly from the front or rear of your car and if set correctly will improve your cars cornering ability considerably, by providing increased traction. This simple to make adjustment is considered by many to be one of the most effective changes you can make to your car for better handling. |

|

Hints, Tips and Information

Look after your Gears

In RC there are a number of different gear teeth sizes we tend to use, based on two systems. Imperial and metric. |

|

RC Models:

|

Radio & Motors: |

Other

Accessories: |