|

|

|

|

Tamiya Ford Bronco 1973 - 58436 (Radio Controlled Model Review)1/10 Scale Electric Rock Crawler - CR-01 Chassis:

Released by Tamiya on June 17, 2009, this CR-01 Chassis based model, is of the Ford Bronco 1973 and is an accurate 1:10 scale model of the Ford Truck that was produced between 1965 and 1977.

▼ Scroll Down for More Images ▼

Rating: 4.5

|

|

|

|

|

|

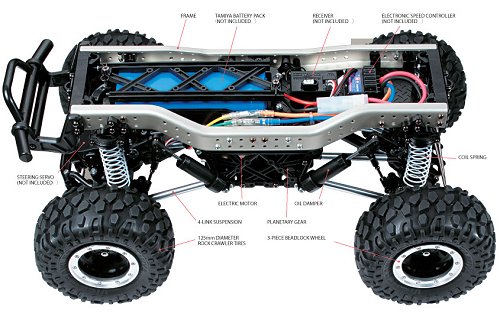

Tamiya Ford Bronco 1973 #58436 CR-01 - Chassis

|

|

Tamiya Ford Bronco 1973 #58436 CR-01

|

Buying a Used Tamiya Rock Crawler (and What to look for)

Make a General Visual Inspection

Check the Body-Shell

If the body shell of your Rock Crawler is broken, ripped or damaged in any way, this can be easily repaired with rubber solution glue. Also, for added protection and if available for your model, fit an under guard to stop dirt and gravel entering the chassis. Drive Shafts and Turnbuckles

Examine the Drive System

The gearbox of your used Rock Crawler should be opened up to check for damaged gears and wear. If there is excessive backlash in the gearing, these should be replaced. A thin coat of grease on the gears is enough to allow smooth operation and reduce further wear. Pinions and Spur Gears

Steering Servo and Servo-Saver

Don't Forget those Bearings

|

|

|

|

|

|

Hints, Tips and Information

My First National

When I first started in RC, way back in the late 1980s, I would turn up to the weekly club meeting, with my Tamiya Boomerang, Acoms transmitter, two sets of crystals, a couple of 7.2v batteries, a charger and a tool box with a wheel spanner and a few spares. |

|

Hints, Tips and Information Gear Differentials

The Gear Differentials, commonly used in Buggys, Trucks, Touring Cars, Monster Trucks and some of the early Tamiya Formula One and Le-Mans cars, are by design more robust than the high maintenance Ball Differentials.

|

|

RC Models:

|

Radio & Motors: |

Other

Accessories: |